Barwell Rubber Products Manufacturing Machines

Barwell Rubber Products Manufacturing Machines Specification

- Type

- Rubber Products Manufacturing Machine

- Material

- High-grade Alloy Steel

- Capacity

- 600 - 800 kg/hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC

- Cooling System

- Water Cooled

- Rolller Speed

- 18-22 rpm

- Max. Diameter

- 180 mm

- Power Consumption

- 25 kW

- Voltage

- 380V / 415V

- Weight

- 3200 kg

- Dimension (L*W*H)

- 3200 mm x 1200 mm x 1700 mm

Barwell Rubber Products Manufacturing Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 10-15 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

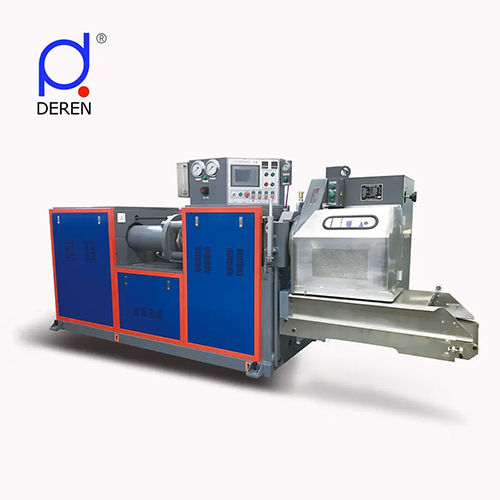

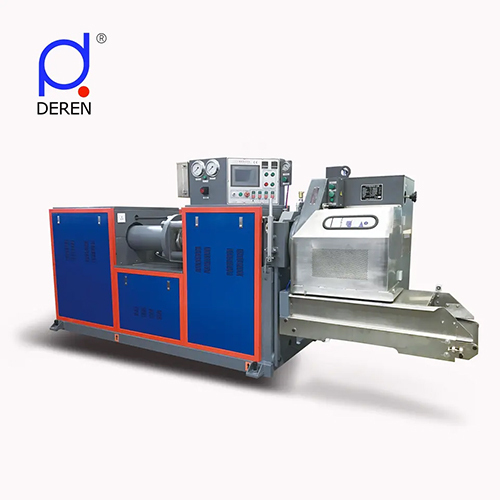

About Barwell Rubber Products Manufacturing Machines

Product details

- Place of Origin : Shanghai

- Condition : New

- Video outgoing-inspection : Provided

- Machinery Test Report : Provided

- Warranty of core components : 1 Year

- Core Components : PLC, Engine, Motor

- Machine Type : High Pressure Precision Preformer

- Weight : 5

- Warranty : 1 Year

- Key Selling Points : Automatic

- Showroom Location : None

- Applicable Industries : Machinery Repair Shops, Manufacturing Plant

- Brand Name : DEREN

- Voltage : Customer Request

- Dimension(L*W*H) : 5.6*1.35*1.85

- Power (kW) : 21.6

- Product name : rubber precision preformer

- Model : JYZH

- Color : Customers Demand

- Keyword : rubber preformer machine

- Usage : Automatic

- Application : Precision Preformer

- Advantage : Accept high-end customization

- Operation method : Manual or PLC controlled

- Operation : Automatic Electric Buttons Controller

- After-sales Service Provided : Engineers available to service machinery overseas

Specification

|

Items |

Unit |

JYZ200H |

JYZ250H |

|

Barrel inside diameter |

mm |

200 |

250 |

|

Total power |

KW |

21.6 |

21.6 |

|

Max. extruding pressure |

MPa |

40 |

25/36 |

|

Max. barrel temperature |

C |

95 |

95 |

|

Max. die diameter |

mm |

125 |

190 |

|

Rubber weight range |

g |

0.1-300 |

0.1-5000 |

|

Rubber blank weight accuracy |

% |

+/-1.0 |

+/-1.0 |

|

Single feeding volume |

L |

25/40 |

60 |

|

Cutter speed |

r/min |

35-300 |

23-300 |

|

External dimension |

m |

4.7x1.35x1.85 |

5.6x1.35x1.85 |

|

Weight |

t |

4.6 |

5 |

Precision Engineering for Maximum Output

Built with top-quality alloy steel and advanced engineering, the Barwell Rubber Products Manufacturing Machine ensures robust performance for demanding rubber production environments. With a capacity of up to 800 kg/hour, it efficiently produces rubber sheets, strips, and customized profiles, making it a reliable choice for manufacturers seeking consistency and scale.

Intelligent Control and Safety Features

The machine comes equipped with a PLC-based control system and an intuitive touch screen interface for straightforward operation and precise adjustments. Safety is prioritized through advanced interlocks and emergency stop mechanisms, ensuring both operator and plant protection during continuous production cycles.

Versatile Feeding and Extrusion Options

Choose between automatic or manual feeding methods, and select from single or twin extruder screw types to best suit your production needs. This flexibility makes the Barwell machine adaptable to a wide range of rubber processing applications, offering manufacturers the ability to tailor output as required.

FAQs of Barwell Rubber Products Manufacturing Machines:

Q: How does the Barwell Rubber Products Manufacturing Machine enhance efficiency in rubber processing?

A: The machine offers continuous operation, automated feeding, and a computerized PLC control system that streamlines production of rubber sheets, strips, and profiles. Together with a high capacity (up to 800 kg/h) and rapid roller speeds, it minimizes downtime and maximizes throughput for rubber manufacturers.Q: What types of rubber products can be produced using this machine?

A: This machine is designed for the production of rubber sheets, rubber strips, and various custom rubber profiles, making it suitable for industries requiring versatile rubber part fabrication.Q: When should a manufacturer opt for single or twin extruder screw configurations?

A: Single extruder screws are ideal for standard, less complex rubber formulations, while twin screw extruders are recommended for enhanced mixing of materials, specialty compounds, or when processing unique profiles that require greater precision.Q: Where is the ideal installation environment for this machine?

A: The machine is best installed in industrial environments with adequate electricity (380V/415V), water supply for cooling, and compressed air at 6 bar. Its robust construction accommodates heavy-duty manufacturing settings typical of rubber processing plants in China or international facilities.Q: What is the process for operating and controlling this machine?

A: Operation involves feeding raw rubber automatically or manually, configuring extruder settings via the touch screen PLC interface, and monitoring production parameters. Safety features and centralized lubrication ensure smooth, reliable, and protected continuous operation.Q: How does the machines safety system benefit operators and production?

A: With built-in emergency stop and interlocks, the safety system quickly shuts down operations during hazards, significantly reducing risk of injury and equipment damage, thereby ensuring a safe and compliant work environment.Q: What are the main benefits of using this equipment in a manufacturing setup?

A: Key benefits include high production capacity, low operational noise, customizable feeding/extrusion options, advanced safety systems, and user-friendly computerized controls, all engineered for efficient, safe, and scalable rubber manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in JYZH RSH Series High Pressure Precision Preform Category

Plastic And Rubber Processing Machinery

Price Range 49000.00 - 52000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Water Cooling

Warranty : 1 Year

Automatic Grade : Automatic

Barwell Rubber Precision Preformer For Rubber Blank

Price Range 29000.00 - 38000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Water Cooling

Warranty : 1 Year

Automatic Grade : Automatic

Barwell Rubber Preformer Cutting Machine

Price Range 29000.00 - 38000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Water Cooling

Warranty : 1 Year

Automatic Grade : Automatic

Barwell Precision Preformer For Rubber Blank Machine

Price Range 49000.00 - 52000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Water Cooling

Warranty : 1 Year

Automatic Grade : Automatic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry